5 Big Problems with Traditional Employee Training

Traditional methods of employee training delivery are profoundly flawed and ineffective. In fact, according to Harvard Business Review, a full 70% of employees say they lack the skills needed in their roles. Meanwhile, a McKinsey survey revealed that just one-quarter of employees believe training improved their performance.

The problem is that there’s no room for error in manufacturing today, and even minor mistakes can result in costly problems related to defects and safety incidents.

Whether using classroom training or even computerized training via a learning management system (LMS), it’s clear that conventional approaches just don’t cut it anymore.

The good news is that manufacturers have a new tool available to make training more effective: connected worker platforms. Below, we discuss five of the biggest problems with traditional employee training and how a connected worker platform eliminates them.

1. Plant Floor Accessibility

Perhaps one of the biggest problems with employee training is that training materials aren’t readily accessible to employees on the job. This creates problems such as:

- Lack of skills reinforcement due to training being disconnected from practicing tasks hands-on

- Forgetting material due to the time elapsed between training and on-the-job experience

- Not being able to refer back to training materials when questions arise

With a connected worker solution, employees can access training content when and where they need it. This helps reinforce skills, improve retention and get real-time support for questions that arise during the process.

2. Employee Engagement

It’s no secret that many employees consider reading through course materials or presentations on an LMS boring. It’s not uncommon, for example, for employees to click through to the end of the training and attempt to pass the test just to get it over with.

This lack of interactivity and employee engagement means employees retain less information from the training, making it less effective than hands-on approaches.

Connected worker software improves employee engagement by allowing workers to practice skills hands-on while receiving training. This, in turn, makes the material more likely to stick, as there is a direct connection between the information they receive and the activity of executing the process.

3. Personalization

Traditional delivery of employee training takes a one-size-fits-all approach, where employees must complete the same set of courses no matter their level of experience. Training isn’t aligned with the employee’s needs or objectives and sends the message that training is just another box to check.

Conversely, connected worker software allows manufacturers to target training content and delivery to the operator’s skill level and role. Guided procedure checklists, for instance, can provide a tailored checklist of steps based on the operator’s experience level.

While a beginner might need to check off all ten steps in a procedure, one closer to certification might only receive reminders for the three most important steps. Fully trained employees might then just receive instructions to perform the final quality check.

4. Real-Time Support and Feedback

Sitting in a classroom or at a computer passively receiving training information deprives employees of real-time feedback. This, in turn, makes it impossible for employees to assess their progress, and for management to provide immediate support as needed.

A connected worker solution can provide real-time feedback and support to accelerate training, whether it’s instant performance data, coaching tips or even support from remote experts.

5. Cost for Value

According to Training Magazine, U.S. companies spent over $100B on training in 2023. In-person classroom training can require significant resources in terms of facilities, materials, and travel—all without delivering the desired results.

Even maintaining a separate LMS comes with its own IT footprint and costs, compared with connected worker software that can be used for multiple activities such as:

- On-the-job training and plant floor knowledge management for materials such as SOPs and work instructions

- Real-time communication and instant messaging, for instance when operators need support or additional components

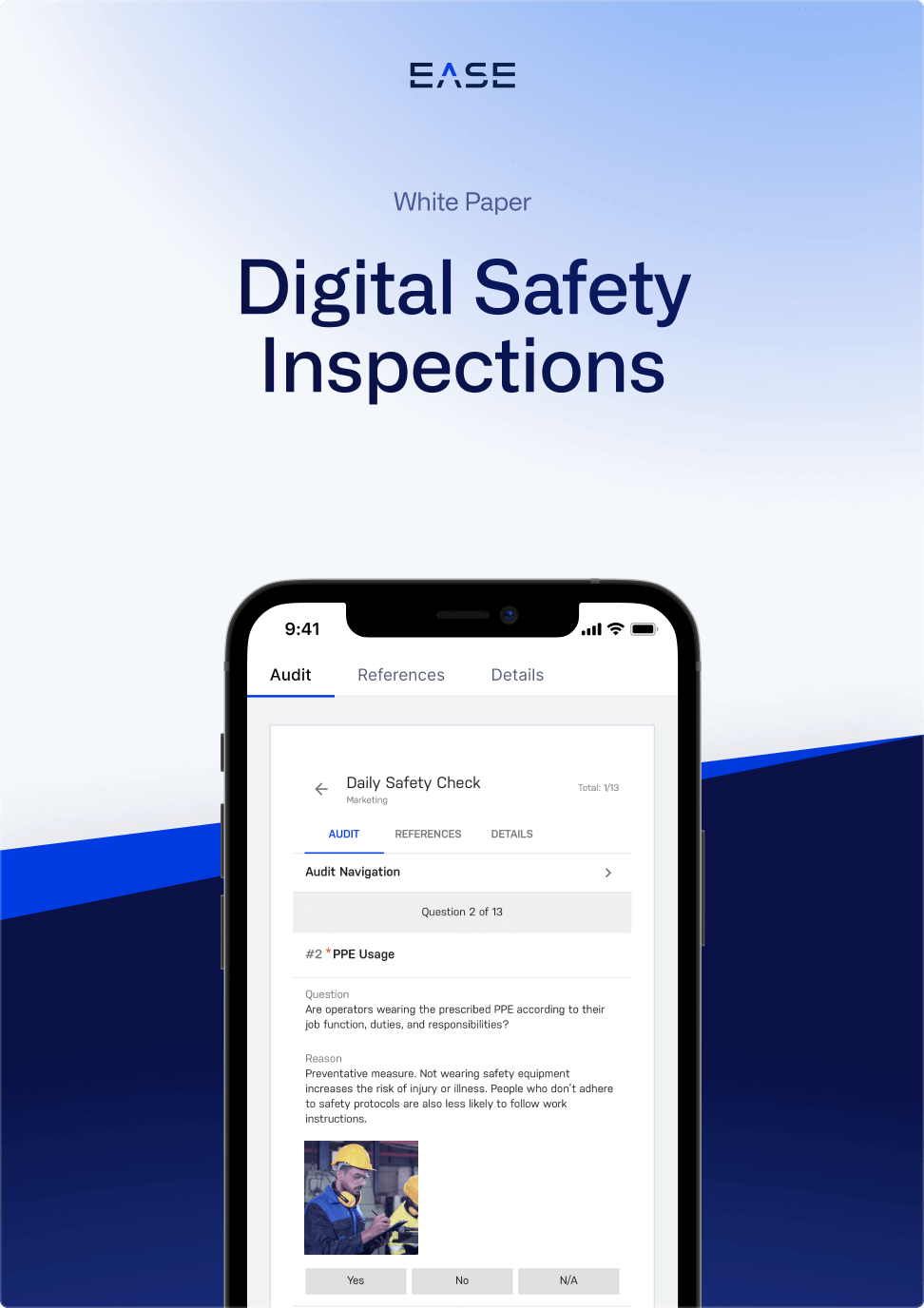

- Plant floor audits and inspections, both for quality and safety

- Closed-loop issue management for accelerating resolution of problems identified with machine data, plant floor observations and audit or inspection findings

The inherent limitations of traditional employee training methods call for a new approach to giving employees the skills they need to excel in their roles. Connected worker software is poised to fill that gap, from improving accessibility and engagement to providing personalized support and feedback. Improving employee training in this way benefits everyone—employees, manufacturers and the customers they serve.