Continuous Improvement in Manufacturing: Process Excellence Frameworks

“Plan your work, work your plan.” It’s a core mantra in continuous improvement that requires forethought and planning, as well as a commitment to executing your business process.

In this article, we explore some of the top frameworks for continuous improvement in manufacturing, including:

- Lean Manufacturing

- Six Sigma

- Total Quality Management (TQM)

- Theory of Constraints

We’ll also take a look at how digital transformation is driving continuous improvements in manufacturing.

Download your free Root Cause Analysis 101 Guidebook for an overview of common root cause analysis tools plus tips and tricks for making them more effective

Read how digital transformation helps to continuously improve manufacturing

Continuous Improvement in Lean Manufacturing

Lean manufacturing technique or simply “lean” describes a collection of tools originating from the Toyota Production System (TPS) in post-WWII Japan. The core aim of lean is to eliminate waste, focusing on three categories of waste or the 3Ms:

- Muda: Activities that don’t create value for the end product or customer

- Muri: Unevenness in production levels

- Mura: Overburden of workers and processes

Lean Tools

Lean encompasses a wide variety of tools to reduce waste while improving efficiency, including:

- Just-in-Time manufacturing: One of the core pillars of the TPS, this principle is about making products as needed to minimize inventory and related costs

- Jidoka: The second core pillar of TPS involves giving machines and workers the ability to detect when abnormalities occur and stopping work immediately

- Kaizen: Kaizen is a quality philosophy that promotes continuous improvement using small, incremental improvements made by all employees that add up over time.

- 5S: Part of the Kaizen philosophy, 5S is a workplace organization tool comprised of 5 steps: sort (seiri), set in order (seiton), shine (seiso), standardize (seiketsu) and sustain (shitsuke)

- Value stream mapping: This is a tool for visualizing processes to identify value-added and non-value-added activities to help with streamlining and improving processes

- Poka-yoke: Error-proofing devices or techniques help prevent defects or make them immediately detectable.

- Visual management: Visual management tools use charts, displays or other visual cues such as Andon lights to communicate key information about processes

When fully adopted by an organization, lean becomes more than a set of systematic tools or a manufacturing discipline. Rather, the elements of lean become a unifying philosophy driving how the company operates and addresses problems, helping establish a company culture of quality.

The Six Sigma Methodology

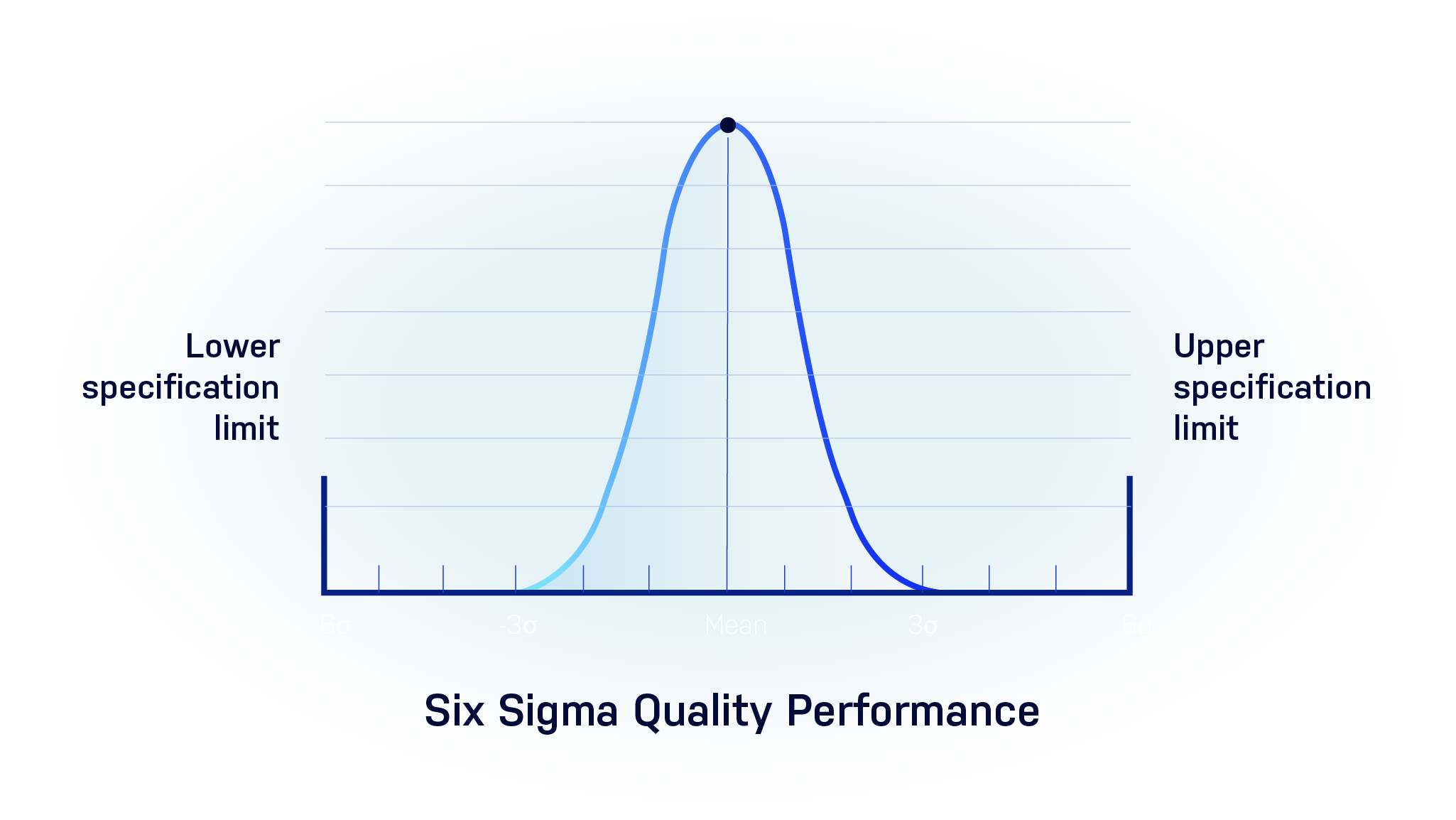

Six Sigma is a data-driven methodology focused on minimizing defects and variation. This approach to continuous improvement in manufacturing centers on applying data and statistical analysis to process control. This methodology was developed by Motorola engineer Bill Smith in 1986, and has since been adopted by leading companies such as GE, Ford and Honeywell.

Six Sigma refers to the number of standard deviations or sigma around the mean under a normal distribution (bell curve). Achieving Six Sigma quality equates to a defect rate of 3.4 parts per million, or nearly defect-free processes.

DMAIC Cycle

Six Sigma is built around the DMAIC cycle, which stands for define, measure, analyze, improve, and control, emphasizing systematic approaches to quality:

- Define: In this phase, the problem itself is clearly delineated, as are project goals, stakeholders, customer requirements and the process needing improvement.

- Measure: The measure phase aims to achieve data collection on current process performance, helping establish a baseline for assessing improvement.

- Analyze: In this phase, teams analyze the data for process variation and perform root cause analysis. Here statistical analysis is central to pinpointing factors impacting quality.

- Improve: The improve phase is where solutions are developed and tested, with the goal of directly addressing the causes identified in the previous step.

- Control: Here the focus is sustaining improvements over time. This requires process monitoring and implementing controls to maintain Six Sigma quality levels.

The DMAIC process largely mirrors and is an extension of the PDCA framework, which we discuss below.

Total Quality Management (TQM)

Total quality management (TQM) is a comprehensive framework for continuous improvement originally developed by W. Edwards Deming, one of the founding fathers of quality management. TQM focuses on statistical process control, data-driven decision-making and organization-wide participation in quality.

TQM is centered on the Plan-Do-Check-Act (PDCA) process approach, also called the Deming Cycle:

- Plan: Setting objectives, defining and documenting processes and standards

- Do: Implementing processes, conducting employee training, executing projects

- Check: Collecting data to measure KPIs against objectives to identify trends and evaluate effectiveness, such as with layered process audits

- Act: Taking action based on data collected in the check phase, including adjusting processes and implementing corrective action

TQM Tools

TQM utilizes a range of tools and techniques that overlap with other continuous improvement frameworks. These include:

- Process mapping to visualize processes and opportunities for improvement

- Statistical process control (SPC) to monitor processes and reduce variation

- Fishbone (Ishikawa) diagrams to facilitate brainstorming sessions for identifying potential causes of problems

- 5 Whys analysis for digging into successive layers of a problem during root cause analysis

- Employee participation to involve people at all levels in the organization in quality efforts and building a culture of quality

Theory of Constraints

The Theory of Constraints is a management philosophy aimed at improving efficiency by eliminating constraints that stand in the way of continuous improvement efforts. Emerging as a response to the limitations of traditional management techniques, the Theory of Constraints takes a more holistic approach to improving system-wide effectiveness, focusing on the most critical bottlenecks.

The Theory of Constraints was first presented by physicist and management expert Eliyahu M. Goldratt in 1984, and has since been widely adopted by many manufacturing organizations.

Theory of Constraints Tools

The Theory of Constraints incorporates multiple strategies and tools aimed at identifying and managing constraints, such as:

- Concentrating efforts: The Theory of Constraints emphasizes concentrating the organization’s efforts and resources on addressing the most critical constraints hampering business performance.

- Prerequisite tree: This tool helps organizations identify constraints by mapping process prerequisites.

- Five focusing steps: The problem-solving process includes five steps aimed at continuous improvement. These are: identifying the constraint, exploiting it, subordinating all else to the constraint, elevating the constraint, and going back to step one to identify new constraints.

- Buffer management: The concept here is to create buffers or controlled inventories so that variations can be absorbed without risk to quality, also reducing the risk of bottlenecks.

- Drum-buffer-rope (DBR): The DBR system ensures production rates are set according to the capacity of the constraint, smoothing out the process while preventing overproduction or underproduction. The drum is the pace-setter or constraint, the buffer is the controlled inventory that protects against disruption, and the rope is what allows communication between the constraint and upstream processes.

4 Ways Digital Transformation Is Driving the Continuous Improvement Process

The growing number of companies increasing investment in digital transformation shows that Industry 4.0 delivers real, measurable value in continuous improvement. Organizations that integrate digital technologies into their operations are part of a sea change revolutionizing the manufacturing industry, and helping companies streamline their production processes, improve product quality, and boost productivity.

Here are real-life continuous improvement examples of how digital transformation drives ongoing improvement and gives forward-thinking companies a competitive edge:

Machine Learning

Machine learning or artificial intelligence (AI) is a fast-growing segment of today’s digital transformation wave. Manufacturers in particular are focusing on AI for a wide variety of use cases, such as:

- Supply chain optimization

- Predictive maintenance

- Transportation and logistics

- Process improvement

- Quality control

Wayfair, for instance, was an early adopter of AI, applying the technology to logistics and shipping. The ability of the company to continuously adjust which products they sent to different ports helped reduce inbound logistics costs by a staggering 7.5% amid pandemic-driven demand fluctuations.

Cloud Computing

According to Gartner, cloud computing remains one of the top drivers of Industry 4.0 investments, expected to reach $597 billion in 2023. The ability to store data in the cloud, rather than manage costly on-premise manufacturing software systems, now means manufacturers can deploy various applications while maintaining a comparatively small IT footprint.

Applications range from enterprise platforms like manufacturing operations management (MOM) and enterprise resource planning (ERP) software to industry-specific solutions like layered process audit (LPA) software.

In the case of LPA software, cloud technology enables greater visibility into manufacturing processes and systems by providing real-time data from audits. People can complete checks on mobile devices and immediately upload findings to the cloud, which are then distilled into actionable insights for leaders.

As an example, one global tire manufacturer uses LPA non-conformance findings to trigger a fast look across all related machinery using custom tags in the audit question library. This quick response lets them quickly identify systemic issues with an outsized impact on quality.

Watch Our Free Webinar on LPA Improvement

IIoT and Edge Computing

Industrial Internet of Things (IIoT) sensors in plant devices have become a core digital transformation catalyst in manufacturing applications such as predictive maintenance, inventory management, and equipment optimization.

Edge computing, which refers to data processing near its source (the network edge), has also expanded manufacturer capabilities around harnessing production data to drive continuous improvement.

Automotive manufacturers use IIoT sensors on machinery to monitor and process performance data at the edge. This lets them quickly pinpoint maintenance issues and inefficiencies, with real-time analytics to drive plant floor decision-making.

For instance, smart factory technology lets automotive manufacturers use IIoT sensors to detect abnormal machine vibrations and repair equipment before it breaks down, reducing unplanned downtime. IIoT sensors combined with edge computing also allow them to collect and analyze production line data for identifying bottlenecks and process improvement opportunities.

Connected Frontline Worker Technology

LNS Research reports that manufacturers are achieving big successes with connected frontline worker technology, with four in five transformation leaders achieving meaningful corporate value from implementation.

Connected worker technology encompasses a suite of tools used for improving quality and efficiency, including:

- Digital procedure checklists, remote engineering support, and troubleshooting guides to give operators on-the-spot access to vital information

- Software applications for conducting digital shop floor audits and inspections

- Bi-directional communication tools, such as instant messaging for connect operators with added support and real-time answers to questions

Achieving Continuous Improvement in Manufacturing Through Process Improvement

Continuous improvement is a journey, not a destination. Each of the frameworks discussed at the top of this article provides a roadmap for the journey, empowering you to implement continuous process improvements, remove workflow bottlenecks, and improve quality and customer satisfaction.

Digital transformation is rapidly changing the manufacturing landscape today, with even minor process improvements potentially providing significant ROI. Those companies willing to take the leap are gaining a competitive advantage over those who adopt a wait-and-see approach. However, it’s critical to avoid “shiny object syndrome,” instead taking the time to identify an existing problem and then exploring how to solve it with digitization.

Plan your work, work your plan, and be ready to adapt along the way.