Digital Safety Inspections Software: Solutions for Keeping New Workers Safe

Keeping New Workers Safe with Digital Safety Inspections

Employees on the job for less than a year made up nearly 30% of workplace injuries in 2020, according to the latest Bureau of Labor Services data available.

The risks are especially great for manufacturers needing to fill roles amid the ongoing skilled labor shortage and large-scale resignations of experienced workers.

So how can companies reduce risks to new workers? Beefing-up training programs and a focus on prevention are key, as is proactively verifying compliance with workflow safety protocols.

In this context, insights gained through frequent digital safety inspections are critical to identifying unsafe behaviors and conditions and giving new employees the support they need. Today we’re looking at how companies can do a better job keeping new workers safe, focusing on risks to new employees and best practices for the inspection process.

Download a free whitepaper on Why and How Digital Safety Inspections Help Manufacturers Work Safer

Why New Employees Are at Heightened Risk

There are several reasons why workers new to their roles are more likely to be involved in on-the-job accidents, including:

- Unfamiliarity with the process: New employees may be less familiar with the process and its required safety protocols. In some cases, people may be more focused on the details of the operation than its inherent safety risks.

- New to your plant: A new workplace comes with new hazards that the employee hasn’t been exposed to previously. If a culture of stringent safety was not prioritized at their previous place of employment, their outlook on safety may take time to change.

- Hesitancy to speak up: New employees may not feel comfortable speaking out about unsafe conditions or behaviors they observe.

- Less training: Those new to your company haven’t received as much safety training overall compared with other employees.

Benefits of Digital Inspections to Help Protect New Workers

Regular or even daily inspections are crucial to protecting new workers. Some companies incorporate safety into other quality checks such as layered process audits, ensuring frequent verification of high-risk items.

Frequent safety checks are especially important for protecting new workers, allowing companies to:

- Verify process compliance with regulatory requirements to minimize mistakes that can lead to quality or safety problems

- See whether employees can both explain and demonstrate safety protocols, such as how to put on specialized personal protective equipment (PPE) correctly

- Increase awareness of hazards through repeated emphasis and attention

- Evaluate and optimize training effectiveness to ensure employees are getting the information they need to do their jobs right

- Solicit feedback in a one-on-one setting where employees may feel more comfortable sharing concerns

- Reinforce a culture of safety by showing operators that you care enough to ask their opinion

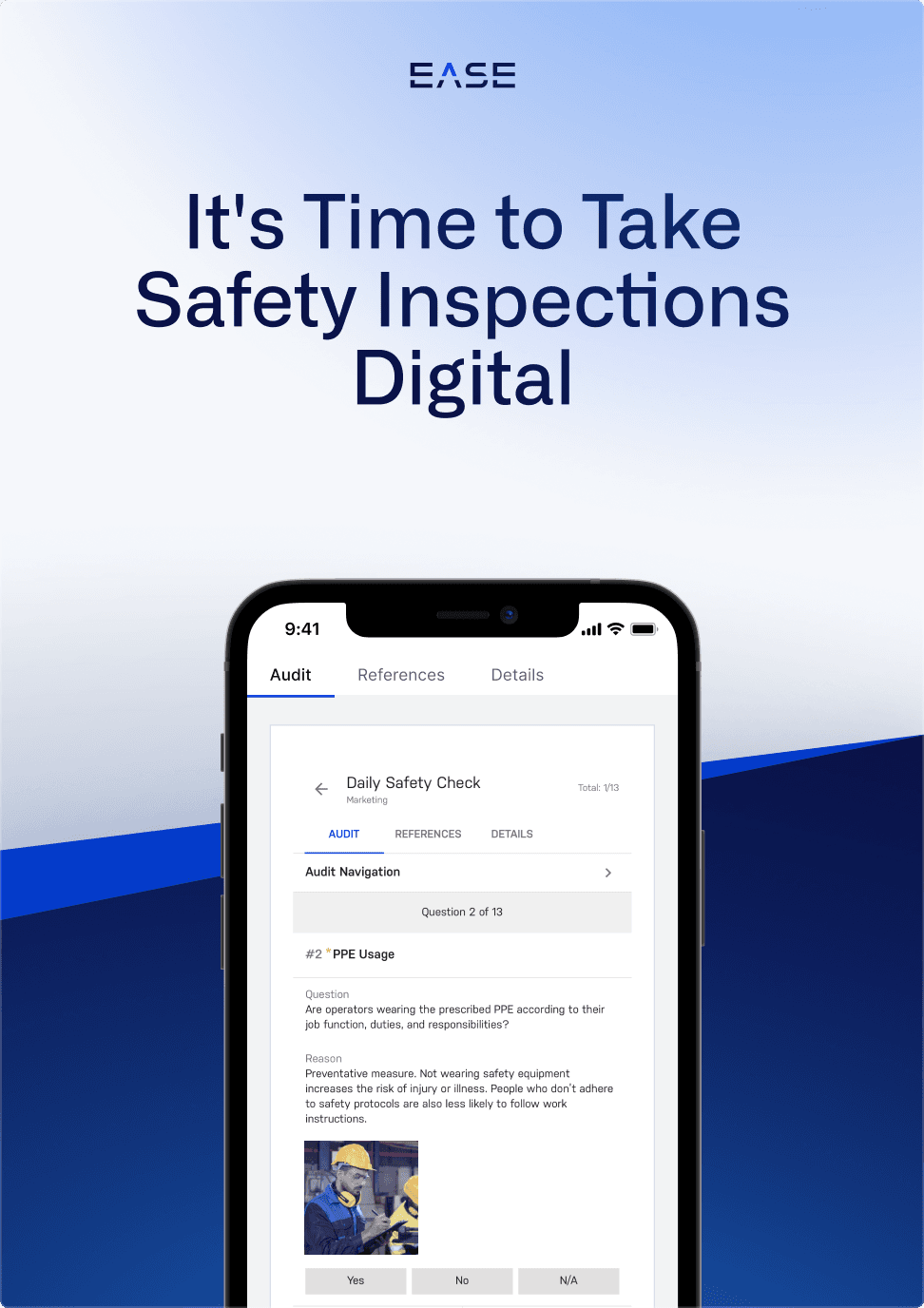

Enhance Worker Safety Management with Digital Inspection Software

While many plants conduct regular safety inspections, traditional approaches involving pen-and-paper checklists are inefficient and create barriers to solving problems. Using a digital inspection platform helps companies streamline and get more out of safety inspections by making it easy to:

- Update checklists: Paper checklists make it hard to change out questions, such as when a near-miss highlights a new hazard needing special attention.

- Address process-specific risks: Different processes have unique risks that people need to be aware of. Asking generic questions on a static checklist, for example, whether an operator is following safety protocols, is less effective than questions that zero in on known risks in the process.

- Make compliance reporting easier: Since inspection data collection and reporting are automated, the adoption of digital inspection technology makes it easier to complete safety audits and compliance reporting efficiently.

- Complete more checks faster: Fast, frequent checks are the key to catching problems before they lead to incidents. Automated scheduling, notifications, and reporting in real time help complete more inspections quickly, as does being able to complete audits on a mobile device.

- Close the loop: A digital safety inspection platform like EASE makes it simple to record on-the-spot mitigations, document nonconformances, and assign follow-up items to responsible parties.

- Gain buy–in: Making inspections quick and minimizing paperwork with digitization helps reduce the burden of inspections on your team. The ability to effectively resolve issues quickly also demonstrates a commitment to safety and promotes buy-in to create a culture of safety.

Increasing the number of new workers is imperative to addressing the manufacturing skills shortage and challenges associated with the Great Resignation. At the same time, new employees are at greater risk of workplace injuries, making safety inspections more important than ever in plants. A digital safety inspection platform can make these checks more up-to-date, efficient, and effective, while also helping build a culture of quality. It can help digitize, customize, and optimize new worker safety.