Understanding the True Cost of Employee Turnover

An average of 4 million U.S. workers quit their jobs every month throughout 2022 according to U.S. Bureau of Labor Statistics data.

Despite recession concerns, demand for workers remains high, especially in manufacturing which has long faced a shortage of skilled employees.

Given these challenges—and the steep cost of employee turnover—many employers are placing increased emphasis on employee retention. While these efforts tend to focus on areas like compensation and professional development, there’s one commonly overlooked element that also impacts turnover: workplace safety.

With that in mind, let’s take a look at what manufacturers need to know about employee turnover and how creating a culture of safety can improve employee retention.

Learn more about The Great Resignation and How Layered Process Audit Software Can Help

What Is Employee Turnover?

Employee turnover refers to the number of workers that leave a company over a given period of time. This number includes voluntary turnover, or the number of employees who quit, and involuntary turnover, referring to those who are fired.

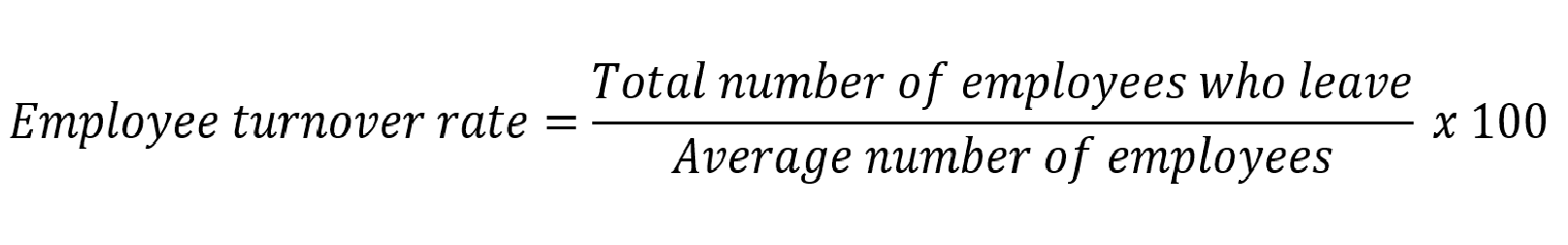

Employee turnover is calculated by dividing the number of employees who leave an organization by the average number of workers in the specified time frame, multiplied by 100.

Employee Turnover Costs at a Glance

High turnover represents a significant financial drain for companies, especially in manufacturing where it can be difficult to replace skilled workers. In fact, according to research from Gallup, it costs one to two times a worker’s annual salary to replace them.

Let’s say your plant has 100 employees, an average salary of $35,000 per year and a turnover rate of 20%. In this scenario, the company would lose up to $1.4 million to turnover every year.

Why is the cost so high? Many factors contribute to the problem, including:

- Recruiting and hiring costs

- Onboarding and training costs

- Paying new employees who aren’t fully productive yet

- Paying overtime to cover open shifts

- Loss of productivity while positions sit unfilled

Hidden Turnover Impacts

While turnover can easily cost manufacturing organizations millions every year, these are just the obvious costs. The reality is that the true costs run far deeper, and often cannot be measured directly.

When workers quit and jobs are unfilled, for example, the result is typically an increased workload for remaining employees. This itself fuels more turnover as burnout leads more employees to quit.

Other impacts that can be difficult to quantify include:

- The loss of talent, including reliable employees, innovators and problem solvers

- Negative impact on company morale as people see colleagues leaving

- Potential loss of business due to quality issues or difficulty filling orders

The Safety-Turnover Link

Not surprisingly, the top reasons people leave their jobs are pay, lack of advancement opportunities and lack of flexibility. One factor that’s less talked about, however, is safety.

Research shows a distinct connection between workplace safety climate and lower employee turnover. A 2020 study in the International Journal of Occupational Safety and Ergonomics, for instance, showed that a positive safety climate reduced turnover intention across a wide number of industries.

If a strong culture of safety reduces turnover intention, that also means poor safety culture contributes to higher turnover. This, in turn, fuels added safety risks due to understaffing and the loss of experienced workers.

Consider, for example, data reported in EHS Today showing that 42% of workers’ compensation claims in 2021were filed by employees on the job less than a year. It follows, then, that rising turnover would increase the proportion of newer workers, potentially leading to more workplace injuries.

Safety incidents themselves hurt company morale, while unaddressed hazards make workers think that management doesn’t care about their safety. This is an important consideration given that this perception can drive workers to seek employment elsewhere.

Fostering a Culture of Safety with Plant Floor Inspections

Fostering a culture of safety is an important part of retaining your best workers and reducing turnover. Interestingly, one study in Safety and Health at Work showed that leadership commitment and supervision of workplace safety heavily influence whether an employee intends to leave.

Plant floor inspections are a key part of safety culture, demonstrating a commitment to safety while ensuring people follow safety protocols. Regular checks reinforce safety culture by:

- Showing workers that management cares about their wellbeing

- Creating opportunities for leaders to give feedback, including recognizing workers for doing things right

- Creating opportunities for workers to give feedback, such as if they don’t have required safety equipment or are feeling burned out

- Improving onboarding and training through one-on-one conversations about safety procedures

In addition to helping create a culture of safety, all of the above benefits are also linked to higher employee retention.

Turnover costs companies millions of dollars every year, and there is an undeniable link between safety culture and employee retention. Building a culture of safety with plant floor inspections can help address the problem, and using a safety inspection app like EASE further helps simplify scheduling, streamline reporting and close the loop on findings. This increased visibility allows companies to find and resolve hazards faster, showing employees a genuine commitment to their safety.